In 2023, Li Jialiang, Deputy Mayor of Panzhou City, visited our company for inspection

2023-11-01

On October 3rd, Li Jialiang, member of the Standing Committee of the Panzhou Municipal Party Committee and Executive Vice Mayor, led personnel from relevant departments of the city to conduct a safety inspection at our company.

Guizhou Zisenyuan Group Investment Co., Ltd

briefing

Issue 17, 2023

Hosted by: Company Party Committee, Trade Union, Office, November 1, 2023

Li Jialiang, Deputy Mayor of Panzhou City, visited our company for inspection

On October 3rd, Li Jialiang, member of the Standing Committee of the Panzhou Municipal Party Committee and Executive Vice Mayor, led personnel from relevant departments of the city to conduct a safety inspection at our company.

Subsequently, Deputy Mayor Li Jialiang, personnel from relevant departments of the city, as well as management personnel from the company and the mine, conducted a safety inspection at the underground site of Zhongheng Coal Mine.

Company Announcement: Results of Inspection and Evaluation of Safety Production Standardization Management System in the Third Quarter

To strengthen the main responsibility of the company's coal mine safety production, urge the coal mine to gradually establish a long-term mechanism for self-restraint and continuous improvement of safety production, strengthen the standardized management of coal mine safety production, consolidate the foundation of coal mine safety production, effectively prevent and contain major accidents, and promote the continuous and stable improvement of the company's safety production situation. According to the "Basic Requirements and Scoring Methods for Coal Mine Safety Production Standardization Management System (Trial)" (Coal Safety Supervision Administration [2020] No. 16) and the company's notice on issuing the "Guizhou Zisenyuan Group Investment Co., Ltd. Safety Production Standardization Management Measures" (Company Issue [2023] No. 19), led by the company's deputy general manager of safety, and with the cooperation of company leaders and safety production departments, a safety production standardization management system inspection and evaluation work was carried out for the company's coal mines in the third quarter of 2023.

On October 13th, the company issued document [2023] 073, reporting on the inspection and evaluation of the safety production standardization management system in its coal mines for the third quarter of 2023. The inspection and evaluation results are as follows: Zhongheng Coal Mine scored 76.02 points, Honghui Coal Mine scored 82.86 points, Mangyuan Coal Mine scored 80.49 points, Chaoyang Coal Mine scored 77.87 points, and Yangchangpo Well District scored 77.52 points; The second level mines are Honghui Coal Mine and Mangyuan Coal Mine, while the third level mines are Zhongheng Coal Mine, Chaoyang Coal Mine, and Yangchangpojing District.

The document reported the main problems and common issues in the inspection and evaluation, and put forward requirements for the next step of work.

According to the notice issued by the company on the issuance of the "Guizhou Zisenyuan Group Investment Co., Ltd. Safety Production Standardization Management Measures" (Company Document [2023] No. 19), rewards and punishments have been given to coal mines that meet the second level standards or above and win the first place, as well as those that finish last.

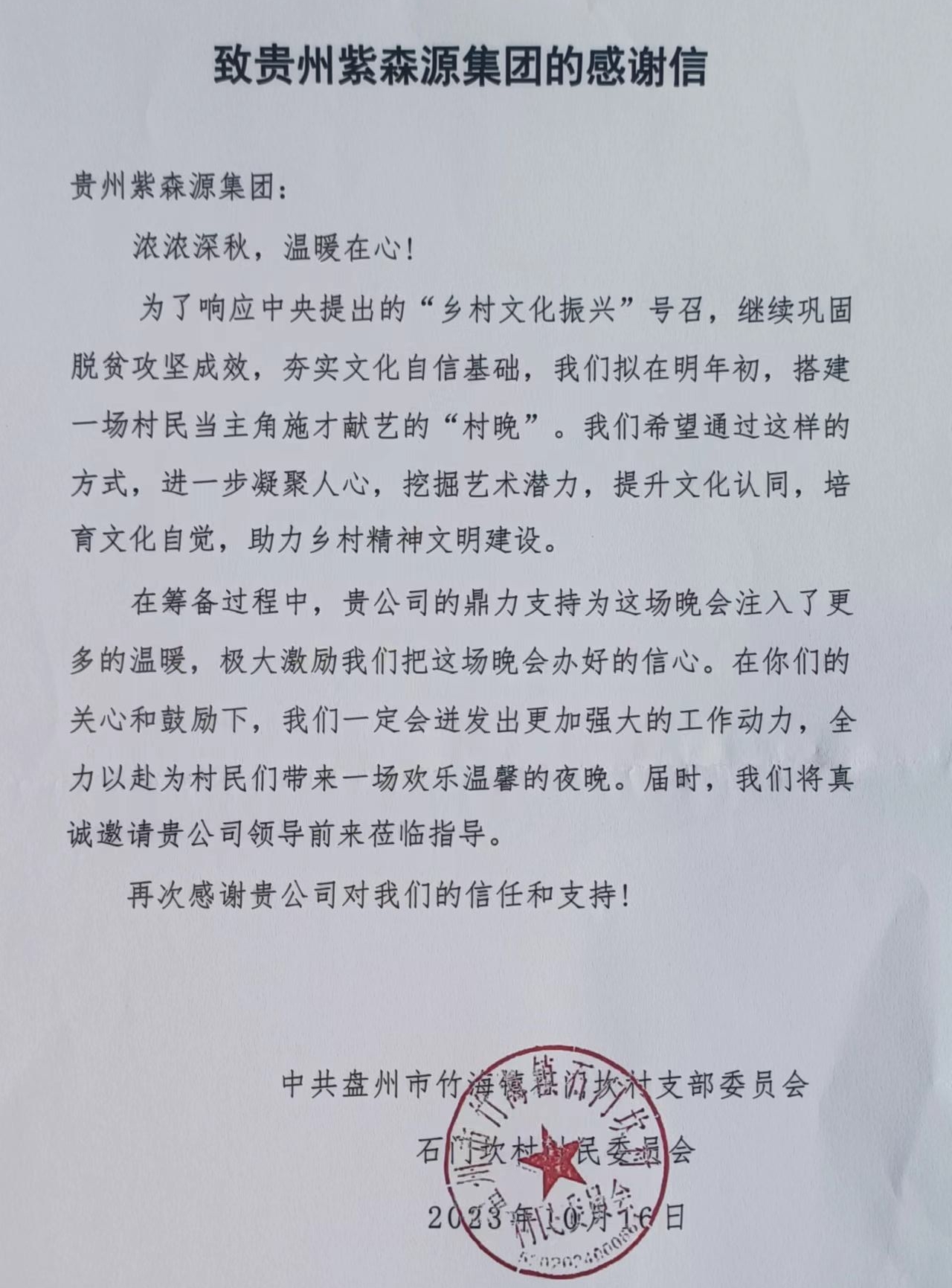

The company supports the "Rural Cultural Revitalization" campaign

On October 17th, the company received a thank-you letter from the Party branch committee and village committee of Shimenkan Village, Zhuhai Town, Panzhou City, expressing gratitude for our company's response to the central government's call for "rural cultural revitalization", strengthening the foundation of cultural confidence, and assisting in the construction of rural spiritual civilization through donations.

The group company held a safety production office meeting in October

——Summarize the safety production work for October and arrange for November

1、 Each unit reported on the completion status of the October work arranged for the company's safety production office meeting on September 28th; Reported on the safety production and safety production standardization management system work of our unit in October, as well as the shortcomings in the work, raised the problems that need to be solved to the company, and planned and arranged the safety production work for November.

2、 Vice General Manager of Safety, Qu Jiabi, reported on the company's safety production inspection in October, the impact of mechanical and electrical transportation equipment, the situation of exceeding the limit of mine gas and carbon monoxide, the work injury situation in various mines, the inspection and punishment situation, the punishment situation for anti "three violations" activities, and the existing problems.

He requested all units to develop and improve control measures in accordance with the requirements of the "November 2023 Safety Risk Analysis and Evaluation Report and Control Table" issued by the company, strengthen supervision and inspection, track and supervise the implementation of risk control measures, and ensure safe production.

Requirements for safety production work in November: 1. The current safety situation is not optimistic. In October, two roof accidents occurred successively in Liupanshui City, namely the roof accident at the 11803 mining face of Zhidu Coal Mine on October 15 and the roof collapse at the left side drilling site of the 110802 transportation roadway excavation working face of Yingyingshan Coal Mine on October 22. After the accident, the Energy Bureau of Liupanshui City and the Energy Bureau of Guizhou Province successively issued relevant documents on roof management, and clarified that the coal mining working face of the roof that adopts blasting coal and single hydraulic support and hinged roof beam management must immediately stop production operations and carry out sealing treatment. In response to these two accidents, we must also take into account the "9.24" accident at Shanshanshu Coal Mine, deeply learn from the painful lessons of the accidents, strengthen the investigation of various risks and hidden dangers, focus on rectifying various problems and hidden dangers, and turn passivity into proactivity. 2. Strengthen the rectification of problems and hidden dangers in the self inspection of safety production (transportation system, safety monitoring system, self rescue facilities and equipment, fire prevention and extinguishing, roof management, major issues, coal mine power supply, gas prevention and control, emergency mechanism, safety training, water hazard prevention and control, hidden disaster factors survey, personnel positioning system and concealed work face) and mechanical and electrical transportation equipment (18 ledger items such as belt conveyors, winches, scraper conveyors, overhead passenger devices, starting switches, etc.). In the rectification of problems or hidden dangers in the self inspection of the above-mentioned tackling and mechanical and electrical transportation equipment by coal mines and companies, coal mines are the responsible unit for the rectification of problems and hidden dangers, and must attach great importance to it. Coal mines strictly follow the five implementation requirements for rectification and acceptance, and report to the company for acceptance after passing the acceptance inspection. Strengthening the maintenance and corresponding improvement of the rectification results of self inspection problems and hidden dangers, the company's coal mines have passed this round of anatomical investigation, and there are many problems. Each mine can only increase the rectification efforts, rectify all the problems found by the coal mines, the company, and the management department, and continue to maintain and continuously improve after passing the acceptance, consolidating our safety foundation work. 3. Safety education and training situation. At present, the training on the use of self rescue devices for all personnel entering the well is still of utmost importance. Each coal mine must continue to prioritize the training on the use of self rescue devices. Those who do not know how to use self rescue devices are not allowed to enter the well, ensuring the effectiveness of blind wearing within 30 seconds. The company will continue to arrange personnel to supervise and implement it. In addition, we will conscientiously carry out safety education and training for the second phase of the company's underground on-site team leaders, safety officers, tile inspectors, and staff in the second half of the year. 4. Continue to promote the construction of demonstration teams in various coal mines and the standardization of safety production. (1) In terms of team construction, currently 15 teams have passed the acceptance inspection of Zhongheng Coal Mine, 3 teams have passed the acceptance inspection of Honghui Coal Mine, 2 teams have passed the acceptance inspection of Mangyuan Coal Mine, and 4 teams have passed the acceptance inspection of Yangchangpo Well Area. Each mine will strive to re accept some teams that have passed the acceptance inspection in November, and all teams must pass the acceptance inspection by December of this year. (2) In terms of promoting safety production standardization work, although various mines have achieved certain results in safety production work in October based on September, they are still far from the first level standardization goal. Each coal mine still needs to explore potential, make great efforts, and vigorously promote safety production standardization work. Construction teams that consistently fail to advance in safety production standardization will undergo shutdown learning. 5. Strengthen the management of pyrotechnic devices. (1) Each coal mine must attach great importance to the management of various aspects such as storage, transportation, use, information reporting, and delivery time of handheld devices for civil explosive materials, and no mistakes should be made in any aspect. (2) The responsible persons in charge of each mine should allocate time and energy to strengthen the management of explosive materials, conduct full process control of the arrival, storage, and transportation of civilian explosive materials every month, ensure clear and accurate management of the situation and quantity of civilian explosive materials, timely grasp the storage, use, and return of civilian explosive materials, timely discover problems and supervise the rectification of safety hazards, and plug safety management loopholes. (3) The classification and storage of blasting materials before blasting (box locking management), the management of standing guard and personnel evacuation must be implemented in accordance with requirements, and the box locking management of the blasting busbar (the three person interlocking blasting management system must be strictly implemented). 6. Format for reporting the reasons for carbon monoxide exceeding the limit alarm caused by blasting. (1) Explosion smoke triggered over limit alarm: XX (location) explosion, smoke triggered sensor alarm. (2) Overlimit alarm caused by exhaust gas from transportation equipment: XX (transportation equipment name) is running, and the exhaust gas triggers a sensor alarm. (3) False alarm: False alarm (note specific reasons, such as failure to calibrate during calibration, sensor malfunction, equipment water ingress, etc.). (4) On site carbon monoxide exceeding limit alarm: On site carbon monoxide exceeding limit (note specific reasons, such as carbon monoxide emission from goaf, equipment wear and burn out, non-standard gas welding operations, etc.). (5) Overlimit alarm caused by other reasons: Sensor alarm caused by other reasons (note specific reasons). (6) If the reason for the alarm is not reported according to regulations, the administrative department may impose a fine of 10000-30000 yuan on the coal mine, and the main person in charge may be fined 10000-10000 yuan; If the reason for the alarm is not properly analyzed and filled in incorrectly, a penalty of 50000 to 100000 yuan may be imposed. Please refer to the notice on strengthening the disposal of carbon monoxide over limit alarm issued jointly by the Guizhou Energy Bureau and the National Mining Safety Supervision Bureau, Guizhou Bureau, in the document "Qian Energy Coal Safety [2023] No. 77". 7. Based on the current situation of Wang Shaohui, Director of the Guizhou Bureau of the National Mining Safety Administration, conducting spot checks at Panzhou Coal Mine, the following tips are given: (1) Each coal mine's pre shift meeting must include the work arrangement, safety precautions, work standards, tools and materials to be prepared for the shift, and clearly understand the key contents of documents such as "Kuan'anqian [2023] No. 56", "Liupanshui Party Office [2023] No. 25", and "Panzhou Party Office [2023] No. 29" (all personnel are aware). (2) The problems exposed by the 9.24 accident. The roadway is seriously in disrepair, with belt friction on the roadway walls, rollers not rotating, and carbon monoxide sensors malfunctioning. (All personnel are aware). (3) How to escape in case of a fire underground. All personnel must be aware of the escape route in case of a fire at the work site. Personnel entering the well must be able to blindly wear self rescue devices within 30 seconds, know the installation location of the compressed air self rescue device at the work site, and be able to use the compressed air self rescue device. (4) How to deal with major dangerous situations. Immediately evacuate personnel and report to the dispatch room (all personnel are aware). (5) How is the hidden danger investigation carried out? If it cannot be rectified immediately, a ledger should be established. (Management personnel are aware). (6) How is the gas daily analysis system implemented, and there should be supporting data. (Management personnel must be aware). (7) Coal mine management personnel must be clear about the team structure and personnel allocation of their own enterprise. (8) All personnel must be aware of the meaning of "Double Day" (the 24th and 25th of each month), which means that the entire system will investigate hidden dangers and all staff will oppose the "three violations".

3、 Zhou Xianbing, Deputy General Manager of Mechanical and Electrical Engineering, proposed the call and adjustment of required mechanical and electrical equipment for each mine

The request has been answered. Propose the following requirements: 1. Strengthen the use and management of mechanical and electrical equipment used in each mine, enhance on-site use, maintenance, and upkeep management, and clarify responsibilities for the maintenance of each equipment and implement them to individuals. 2. Strengthen communication with manufacturers to ensure the intelligent functioning of auxiliary systems. 3. According to the requirements of the "Notice of the Provincial Energy Bureau on Issuing the Plan for Uploading Online Monitoring Data of Coal Mine Electricity Consumption" (Qian Energy Coal Safety (2023) No. 46 document), combined with the actual situation, the installation of dual circuit electricity consumption online monitoring and metering devices should be completed before December 31, 2023.

4、 Deputy General Manager of Production Bao Jiming reported on the completion of production tasks in various mines in October

And the reasons for the unfinished tasks were reported along with the existing shortcomings. The production plan for November has been issued. He demanded: 1. Carefully organize the production in November, strengthen on-site management, implement rules and regulations, and achieve excellent and fine mining in the coal mining face to improve the recovery rate of clean coal. 2. Strengthen the various work of coal mining installation and recovery, ensure the safety management and progress of installation and recovery. 3. Seriously carry out the excavation of each excavation head, manage the roof and support, firmly grasp the roof management work, consolidate the foundation of safety production, strictly implement the knocking and asking roof system and the roadway inspection system, 3. Strengthen labor discipline and shift system. The five positions of mine manager and deputy general manager in each mine should conscientiously fulfill their responsibilities as underground shift supervisors. Those who fail to meet the number of shifts should be strictly punished.

5、 Peng Xianglai, the Chief Financial Officer and Minister of Personnel, reported on the production and operation situation and put forward the following requirements: 1. Strengthen work communication to ensure the supply of equipment and materials required by the coal mine. 2. Mangyuan Coal Mine has made work adjustments, and it is necessary to timely understand the ideological dynamics of employees, do a good job in personnel ideological work, promote unity, and maintain the stability of the coal mine. 3. In terms of production and operation assessment, in case of special circumstances, a report should be written and submitted to the company on the reasons for the failure to produce normally. 4. By the end of November, all units must submit their mining plans for next year, as well as their salary distribution and assessment plans by December 15th, to facilitate the company's research. 5. The state has clear regulations on the number of people entering coal mines, therefore, all units should do a good job in setting positions and personnel.

6、 Li Qunduo, Secretary of the Party Committee and Chairman of the Trade Union, put forward the following requirements: 1. Management personnel at all levels must strengthen their learning of relevant laws and regulations, Party policies, and professional knowledge, and further improve their management level. Strengthen the training of employees' professional knowledge and improve their overall quality. 2. Effective measures should be taken in management to move from local breakthroughs to overall capability improvement. Based on the development stage, implementing the new development concept, constructing a new development pattern, and promoting high-quality development. With a sense of mission, responsibility, and urgency, we strive to be the first in the forefront of basic fields. Fully stimulate the enthusiasm, initiative, and creativity of the vast number of employees. We need to have unwavering determination, face the forefront, the main battlefield, major needs, grasp the overall situation, seize opportunities, face problems and difficulties head-on, shoulder the heavy responsibility entrusted by the times, and strive to achieve the company's development goals of self-reliance and self-improvement. 3. Safety production should deeply learn from the lessons of external accidents, draw lessons from them, comprehensively strengthen the investigation of various hidden dangers, promptly deal with problems found, consolidate responsibilities in all aspects, strengthen safety supervision, and not relax at all. We should carry out safety production work with the spirit of extreme responsibility to employees, think from the attitude of being responsible to employees, the company, and ourselves, treat major risks and hidden dangers as accidents, fulfill our responsibilities, dare to take responsibility, improve the system, strictly supervise, and effectively maintain the physical and mental health of employees. 4. Correct decision-making cannot be separated from investigation and research, and the correct implementation also cannot be separated from investigation and research. Managers at all levels should go deep into the front line to do a good job in investigation and research. Efforts should be made to consolidate, optimize, and improve. Build a management team that is politically strong, skilled, and has a strong work style, achieve high-quality development of work, and promote the comprehensive development of coal mines. 5. All cadres and employees of the company unite, under the leadership of the chairman and the company's leadership team, to unify their thinking, understanding, and actions. Form a leadership team that is proficient in business and highly skilled, brave in innovation and tenacious in striving, and continuously make new and greater contributions to the development and growth of the company.

7、 Chief Engineer Zhu Zengxiao was entrusted by General Manager Chen Hua to arrange various tasks for the company. He answered the questions that each unit needed the company to solve, reported on the company's production indicators, work-related injuries, gas control, and other situations from January to October 2023, and summarized the achievements, problems, and shortcomings of each unit's work.

He put forward requirements for safety production in November: 1. Strengthen roof management work. Recently, there have been many sporadic accidents in the roof area. In response to the roof management, the province and city have issued corresponding documents. After the roof accident of one person on the blasting face of Shuicheng Zhidu Coal Mine on October 15th, the Energy Bureau of Liupanshui City issued a notice to immediately stop operations and seal the blasting face. Therefore, all units must ensure that the regulations and measures for on-site roof management are implemented in place, strengthen the management of the upper and lower exits of the mining face working face, strengthen the reinforcement of roadway intersections and water drenched areas, and strictly manage the use of exploratory beams before excavation work. The excavation of thick and soft coal seams should be timely protected to shorten the time of empty roof. Before drilling in each mine, the drilling site must be reinforced, and the work of protecting the roof must be implemented well, especially in areas with soft coal seams and fractured geological structures where drilling is prone to roof leakage. The lessons learned from the October 22 incident of the roof collapse and injury in the Yingyingshan coal mine drilling site are profound. Each mine should learn from this and take measures to improve roof management. Contact the manufacturers as soon as possible for the unfinished online monitoring of the roof of each mine, and complete this work well. 2. In terms of "one communication and three prevention": (1) Each mine shall conduct self-evaluation in accordance with the gas prevention and control capability assessment management measures issued by the provincial bureau, the content and scoring standards of gas prevention and control capability assessment, and promptly rectify any problems. After passing the self-evaluation and reporting to the company for review, they shall apply for evaluation to the regulatory body department, and the communication and prevention department shall supervise and track it. (2) Seriously carry out daily analysis of ventilation and gas, take it seriously, and carry out important measures to timely discover and solve problems every day. If there are abnormalities or fluctuations, identify the causes. The system inspection includes a comprehensive check of the ventilation system conducted by the company and each mine this month. Any existing problems should be rectified in a timely manner, especially those that cannot be guaranteed in terms of cross-section. For those that cannot be solved in a short period of time, there should be a rectification plan. In the future, each mine will inform the company of the monthly system inspection. If time permits, the mine and the company can integrate resources together. Optimize the ventilation system again, seal and reduce the system for those that are not needed in the short term. The more, the more difficult it is to manage. All ventilation facilities should be reliable, and the rectification of anti backflow facilities and interlocks should be in place. (3) Thoroughly carry out the evaluation of conflict resolution, strengthen the management of heart sampling prediction and forecasting, and ensure the authenticity and reliability of data. Each mining face's anti outburst evaluation company strictly controls, and if it does not meet the requirements for rework, it is necessary to fully recognize that any problems in anti outburst are major issues. (4) Strengthen CO prevention and control, strictly manage blasting according to requirements, report before blasting, and strengthen on-site process control. Ensure that the quality of water cannon mud, cannon mud, and sealing mud length meet the requirements, and minimize the value of CO. Regardless of the reason for exceeding the limit, the number of times will be counted, and there will be preventive inspections. The rescue team will carry out relevant work in accordance with the preventive inspection guidelines of the mine rescue team, conduct closed inspections, and promptly report any problems found to the mine and urge rectification. The dust-proof pipe tee shall be arranged as required, the spray dust suppression at each transfer point shall be used well, and the roadway dust cleaning shall be arranged well. 3. In terms of water prevention and control: (1) Prevention of old kilns is the key, and geological prediction and forecasting work should be done well. Geophysical and pre exploration work should be followed up, and the amount of accumulated water at each water point should be calculated. If the water pressure reaches 0.1MP, casing must be installed, and observation boards for water inflow points should be managed. (2) According to the requirements of the provincial bureau, the hydrogeological types of the mines have been rechecked. Currently, the hydrogeological types of the company's coal mines are all moderate, and each mine must strictly follow the "Coal Mine Water Prevention and Control Rules". The Geological Survey Department should provide guidance and revise the "Mine Hydrogeological Type Report" in a timely manner based on the review results. (3) All mines (except for Mangyuan Coal Mine) have completed the installation of water hazard warning and monitoring. We should make full use of water hazard warning and monitoring, and do a good job in daily water inflow statistics and analysis. 4. Normalize the management of hidden and harmful factors that cause disasters. (1) Coal mines are dynamic, and some hidden hazards and disaster factors are generated during the production process. The survey report on hidden disaster causing factors and governance plan are required to be prepared and submitted before October 30th. (2) The main person in charge of the coal mine is the first person responsible for the investigation and management of hidden disaster causing factors. Each mine should combine the report and management plan to implement the measures of the disaster causing factor management plan. It involves gas prevention and control, water prevention and control, fire control, roof management, etc. (3) Relevant functional departments such as the company's safety supervision department, production department, geological survey department, and communication prevention department shall supervise and promote the governance of major hidden disasters according to their own responsibilities. (4) The locations where the mining face has a large roof area should also be marked as hidden hazards to strengthen prevention. For example, the location where the stone door of the excavation face is exposed to the coal should have a roof area to prevent the collapse of the roof and the high roof gas from being affected by dynamic pressure. It is required to design a joint pipe drainage system. 5. Standardization of safety production should prioritize technology. (1) Regulations and measures come first, various construction designs come first, and predictive contact forms come first. One project, one measure, especially for some sporadic projects, measures must be taken first for bottom pulling, alley repair, and coal seam treatment. Without measures, operations cannot be carried out. (2) The roadway is strictly arranged with wind and water pipes and gas drainage pipes according to the design and construction. The provincial bureau has also made a special rectification document on roof management, which scientifically and reasonably determines the support parameters, support strength and methods according to the "one roadway, one design, one side". It is strictly prohibited to organize construction on the work site without following the design requirements, and each mine should implement them accordingly. (3) The waistline is the key to the straightness of the tunnel during tunnel construction. Without water accumulation, the blast hole should be designed according to the requirements, and smooth blasting should be carried out. The tunnel should be well formed and the pipeline should be hung properly, which is conducive to the standardization work. It is necessary to ensure the quality of the project from the source. 6. Strengthen the implementation, tracking, and supervision of work arrangements. (1) Timely grasp the progress of work, many tasks have been arranged, but the specific completion status is unclear. The arranged work sometimes compromises the execution ability of others, either because they do not trust others or because they are afraid of work going wrong. Many tasks have problems in the implementation of this link. (2) Tracking the implementation status is also an effective means to prevent fraudulent behavior, and on the other hand, it is also a form of protection for workers. 7. Document learning, sorting, classification, and management. Especially for important business documents, each business department should collect and grasp the important content, especially in the mining industry. Some personnel are not in the work group, and the mine management leaders need to arrange them. The company's business departments need to follow up on requirements and supervise the work. Currently, some professional personnel have unclear understanding of the requirements of their own profession in some documents, and even do not know, so their work cannot be carried out. 8. Strengthen equipment recycling and installation management. (1) The recycling of fully mechanized mining equipment in coal mining face must implement responsibilities, strengthen on-site control, and strictly implement safety technical measures such as standing guard and manned personnel during object operation, inspection of steel wire ropes, and on-site organizational measures. Responsibilities must be in place, and the person in charge of the on-site team must stick to their position, supervise and coordinate various on-site recycling work, and ensure the safe, orderly, and normal progress of recycling work. (2) The recovery of facilities and equipment in various tunnels of coal mines, especially the reporting of the withdrawal of monitoring probes, measures should be followed up and implemented. (3) At the same time as recycling equipment, multiple sealed channels need to be installed, and some have the problem of simultaneously installing inlet and outlet air ducts. The plan and sealing measures should be strictly controlled by the prevention department, and the on-site sealed mine should strictly follow the measures. (4) Preparation of installation route, and inspection of the operation route of the monorail crane. The mechanical and electrical department should track and implement it. 9. The mining plan arrangement for each mine next year involves many assessments for next year. A preliminary draft will be submitted for discussion before November 15th, and revisions will be made based on the discussion. The final draft will be completed by the end of November.

Relevant Documents

Related News